-

Ever wanted an RSS feed of all your favorite gaming news sites? Go check out our new Gaming Headlines feed! Read more about it here.

-

We have made minor adjustments to how the search bar works on ResetEra. You can read about the changes here.

Southwest passenger injured midflight by engine shrapnel, partially sucked out of plane [UP: 1 dead]

- Thread starter ElectricBlanketFire

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Not everyone is an aviation expert (I am). Honor and shame are...

Anyway shrapnel from uncontained engine failure can doom a flight if it strikes a fuel take or hydraulic lines. I doubt anyone knew the extent of the damage and until you're on the ground, you're in metal tube full of fuel traveling hundreds of miles an hour with zero control on whether you live or die. I imagine it would be pretty traumatic. Even suddenly severe clear air turbulence I experienced on a flight (which a flight attendant told me was the worst she had every encountered in 17 years of flying) had people screaming and crying on a flight I was on

yeah, 2 of these fan blade failures in 2 years is probably pretty concerning to both the manufacturer and Southwest.

Maybe Southwest is working the jets harder than realized. Either way, probably need new protocols to keep a closer eye on the fan blades going forward.

yeah, 2 of these fan blade failures in 2 years is probably pretty concerning to both the manufacturer and Southwest.

Maybe Southwest is working the jets harder than realized. Either way, probably need new protocols to keep a closer eye on the fan blades going forward.

Southwest has a stellar safety record and has the highest volume of flights for a US carrier. I doubt they have widespread issues and probably some sort of revised inspection schedule/procedure is the most that needs to be done.

Southwest has a stellar safety record and has the highest volume of flights for a US carrier. I doubt they have widespread issues and probably some sort of revised inspection schedule/procedure is the most that needs to be done.

Yeah that's basically exactly what I said. ;).

Hah true enough. I'm drinking and about to get on a plane :p

Found some air traffic control audio, everyone involved was very professional.

Thanks for posting. I love to hear these

Military pilots are just different than the normal populace, the nerves/ability to stay calm in such situations is amazing.

Not just military pilots.

I mean I'll never stop flying Southwest, but they need to look at some of the older planes to make sure this doesn't happen again. They have an almost spotless record compared to others considering flight volume and age of their fleet.

Again, it has less to do with their airframes, and more to do with their engines.

Can you elaborate please? I'm genuinely curious.Again, it has less to do with their airframes, and more to do with their engines.

If these planes are designed to fly/land with only one engine and depressurized, why was everyone wailing/ screaming and convinced they were going to die? Does the plane fly more erratically when depressurized? Was it just the visual/sound of the blown out window, O2 masks and apparently blood?

Because a fucking engine exploded while they were flying in a metal tube

"Ladies and gentlemen, this is your captain speaking. We have a small problem. All four engines have stopped. We are doing our damnedest to get them going again. I trust you are not in too much distress."

Those words were spoken by a British Airways 747 captain when all four engines flamed out due to volcanic ash. Smooth and calm as fuck.

https://en.wikipedia.org/wiki/British_Airways_Flight_9

So, how will the people on that plane be compensated? They better all be rich after this, they're likely to suffer years of PTSD from the trauma.

From the link above it seems like she was hit from debris. I had thought that the woman who was hit by debris, and the woman partially sucked through the window, were different individuals. I still don't know if they're one and the same.

In the article it says the women who was sucked out died.

I'm guessing getting partially sucked out of an airplane window due to rapid depressurization probably broke her back and neck and killed her instantly.

Also the cabin depressurized due to a broken window and someone got almost sucked out of the plane and fatally injured.Because a fucking engine exploded while they were flying in a metal tube

The age and health of the airframe of the aircraft is irrelevant if the engine is unable to contain a failure.

"Ladies and gentlemen, this is your captain speaking. We have a small problem. All four engines have stopped. We are doing our damnedest to get them going again. I trust you are not in too much distress."

Those words were spoken by a British Airways 747 captain when all four engines flamed out due to volcanic ash. Smooth and calm as fuck.

https://en.wikipedia.org/wiki/British_Airways_Flight_9

Imagine being a passenger on this flight

The force on your spine from the drag at those speeds would be insaneIn the article it says the women who was sucked out died.

I'm guessing getting partially sucked out of an airplane window due to rapid depressurization probably broke her back and neck and killed her instantly.

.Philadelphia's medical examiner says that a woman killed when she was partially blown out of a Southwest Airlines plane died of blunt impact trauma to her head, neck and torso.

Did the actual metal kill her or getting whipped about against the plane?

I don't think the shrapnel struck her directly. More likely is that when the window broke, she hit the inside wall around the window very hard as she was pulled through it. Just my guess though.

Unless it captured the actual moment of the engine failure, it's probably not worth watching.Surprised video from the interior of the airplane hasn't popped up by now.

https://www.cnbc.com/2018/04/18/pas...n-masks-properly-aboard-southwest-flight.html

flight attendants tell you in the safety instruction before every flight that you have to wear your oxygen masks over your nose and mouth. but many people on the flight did not. not sure what airlines can do when passengers don't pay attention to the safety instructions.

flight attendants tell you in the safety instruction before every flight that you have to wear your oxygen masks over your nose and mouth. but many people on the flight did not. not sure what airlines can do when passengers don't pay attention to the safety instructions.

I mean I'll never stop flying Southwest, but they need to look at some of the older planes to make sure this doesn't happen again. They have an almost spotless record compared to others considering flight volume and age of their fleet.

I know that this shit is incredibly rare, but when I was coming back from WonderCon via Southwest late last month, the entire back end of the plane was causing such a ruckus for the first fifteen minutes that I seriously, literally thought that my life was in danger.

So this news is deeply, deeply unsettling.

The NTSB released an investigative update:

https://www.ntsb.gov/investigations/Pages/DCA18MA142.aspx

I'll post pertinent excerpts:

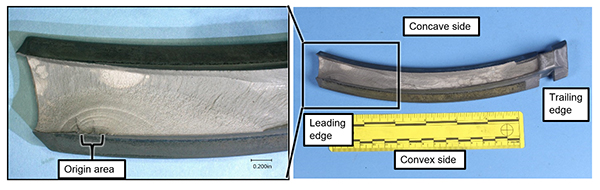

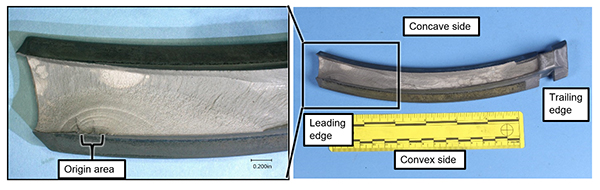

Fracture surface with fatigue indications

Damage to leading edge of left wing

Picture of window 14 with portion of engine inboard fan cowl.

https://www.ntsb.gov/investigations/Pages/DCA18MA142.aspx

I'll post pertinent excerpts:

The No.13 fan blade had separated at the root; the dovetail remained installed in the fan disk. Examination of the No. 13 fan blade dovetail exhibited features consistent with metal fatigue initiating at the convex side near the leading edge. Two pieces of fan blade No. 13 were recovered within the engine between the fan blades and the outlet guide vanes. One piece was part of the blade airfoil root that mated with the dovetail that remained in the fan disk; it was about 12 inches spanwise and full width and weighed about 6.825 pounds. The other piece, identified as another part of the airfoil, measured about 2 inches spanwise, appeared to be full width, was twisted, and weighed about 0.650 pound. All the remaining fan blades exhibited a combination of trailing edge airfoil hard body impact damage, trailing edge tears, and missing material. Some also exhibited airfoil leading edge tip curl or distortion. After the general in-situ engine inspection was completed, the remaining fan blades were removed from the fan disk and an ultrasonic inspection was performed consistent with CFM International Service Bulletin 72-1033. No cracks were identified on the remaining blades.

The No. 13 fan blade was examined further at the NTSB Materials Laboratory; Figure 2 shows a portion of the blade in detail. Fatigue fracture features emanated from multiple origins at the convex side and were centered about 0.568 inch aft of the leading edge face of the dovetail and were located 0.610 inch outboard of the root end face. The origin area was located outboard of the dovetail contact face coating, and the visual condition of the coating appeared uniform with no evidence of spalls or disbonding. The fatigue region extended up to 0.483 inch deep through the thickness of the dovetail and was 2.232 inches long at the convex surface. Six crack arrest lines (not including the fatigue boundary) were observed within the fatigue region. The fracture surface was further examined using a scanning electron microscope, and striations consistent with low-cycle fatigue crack growth were observed.

Fracture surface with fatigue indications

The accident engine fan blades had accumulated more than 32,000 engine cycles since new. Maintenance records indicated the accident engine fan blades had been periodically lubricated as required per the Boeing 737-600/700/800/900 Aircraft Maintenance Manual.

According to maintenance records, the fan blades from the accident engine were last overhauled 10,712 engine cycles before the accident. At the time of the last blade overhaul (November 2012), blades were inspected using visual and fluorescent penetrant inspections. After an August 27, 2016, accident in Pensacola, Florida, in which a fan blade fractured, eddy current inspections were incorporated into the overhaul process requirements.

In the time since the fan blade overhaul, the accident engine fan blade dovetails had been lubricated 6 times. At the time each of these fan blade lubrications occurred, the the fan blade dovetail was visually inspected as required for the fan blades installed in the accident engine.

The remainder of the accident airplane's airframe exhibited significant impact damage to the leading edge of the left wing, left side of the fuselage, and left horizontal stabilizer. (See figure 3.) A large gouge impact mark, consistent in shape to a recovered portion of fan cowl and latching mechanism, was adjacent to the row 14 window (see figure 4; the window was entirely missing. No window, airplane structure, or engine material was found inside the cabin.

Damage to leading edge of left wing

Picture of window 14 with portion of engine inboard fan cowl.

Three flight attendants were assigned to the flight, and an additional SWA employee was in a jumpseat in the cabin. During interviews, the flight attendants and the employee reported that they heard a loud sound and experienced vibration. The oxygen masks automatically deployed in the cabin. The flight attendants retrieved portable oxygen bottles and began moving through the cabin to calm passengers and assist them with their masks. As they moved toward the mid-cabin, they found the passenger in row 14 partially out of the window and attempted to pull her into the cabin. Two male passengers helped and were able to bring the passenger in.

During interviews, the flight crew stated the climbout from LaGuardia was normal with no indications of any problems; the first officer was the pilot flying and the captain was the pilot monitoring. They reported experiencing a sudden change in cabin pressure, aircraft yaw, cockpit alarms, and a "gray puff of smoke." They donned their oxygen masks, and the first officer began a descent. Flight data recorder data showed that the left engine parameters all dropped simultaneously, vibration increased, and, within 5 seconds, the cabin altitude alert activated. The FDR also indicated that the airplane rolled left to about 40 degrees before the flight crew was able counter the roll with control inputs. The flight crew reported that the airplane exhibited handling difficulties throughout the remainder of the flight. The captain took over flying duties and the first officer began running emergency checklists. The captain requested a diversion from the air traffic controller; she first requested the nearest airport but quickly decided on Philadelphia. The controller provided vectors to the airport with no delay. The flight crew reported initial communications difficulties because of the loud sounds, distraction, and wearing masks, but, as the airplane descended, the communications improved. The captain initially was planning on a long final approach to make sure they completed all the checklists, but when they learned of the passenger injuries, she decided to shorten the approach and expedite landing.

Engine Failure Subject of NTSB Investigative Hearing

WASHINGTON (July 24, 2018) — The National Transportation Safety Board announced Tuesday plans to hold an investigative hearing Nov. 14, 2018, as part of the agency's ongoing investigation of the fatal, April 17, 2018, CFM International engine failure on Southwest Airlines flight 1380.

The one-day hearing, scheduled to be held in the NTSB's Board Room and Conference Center, will focus on:

- CFM International CFM56-7 series engine fan blade design and development history.

- CFM International CFM56-7 series engine fan blade inspection methods and procedures.

- Engine containment design and certification criteria.

"This was the first fatal accident involving a U.S. Part 121 air carrier in almost 10 years," said John DeLisi, Director of NTSB's Office of Aviation Safety. "This hearing will be an important part of determining why this tragedy occurred and will provide investigators important factual data regarding the engine fan blade and engine inlet design and certification."

The NTSB conducts investigative hearings to gather sworn testimony from witnesses on issues identified by the NTSB during a major transportation accident investigation. An investigative hearing differs from a board meeting in that no analysis is discussed at the investigative hearing – it is for fact-finding only. Like a board meeting, an investigative hearing is open to the public, affording an opportunity to observe the investigation's progress.

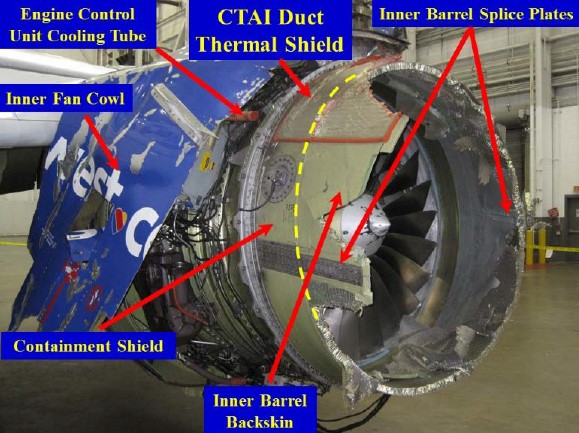

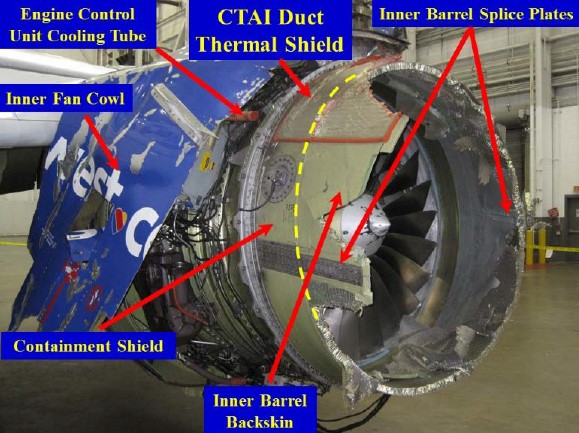

In this NTSB photo-illustration, damaged components of the left engine are identified as viewed from the inboard side of the CFM-56-B engine. During climb out following departure from New York's LaGuardia Airport April 17, 2018, the engine experienced a failure of a fan blade which resulted in the loss of the inlet and cowling. Almost the entire inner and outer barrels of the inlet cowl were missing as were the forward and aft inlet bulkheads. (NTSB Photo-illustration)